TECHNICAL ASSISTANCE

PRODUCT SUPPLY

INSTALLATION AND TRANSFORMATION

TURNKEY PROJECTS

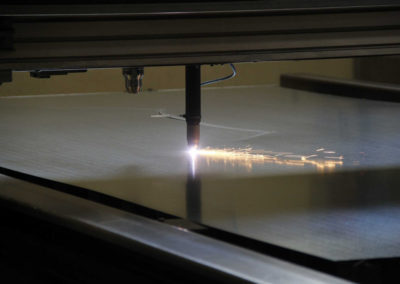

Grinding roll grooving

TECHNICAL ASSISTANCE

Thanks to our long experience ,nationwide network professional competence and distribution ,we can offer technical assistances 24 hours a day , 7 days a week, efficiently and swiftly, to ensure continuity and full service to our customers on mills,silos,riseria,aspiration plants and grain storages.

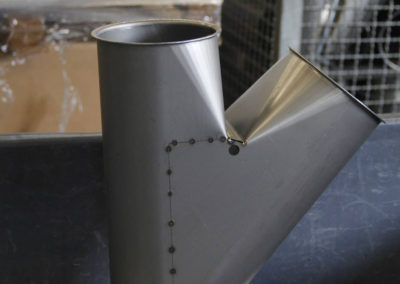

FLOWER ACCESSORIES AND COMPONENTS

BAVUSO deals with milling accessories and parts of industrial milling,aspiration of stainless and galvanized parts ,steel and enamelled,by powder pipes and milling accessories of all kinds.

ASSEMBLY AND PROCESSING PLANTS

Our long experienced company, in the installation,removal,extension and transformation of milling plants and suction,silos, rice mills,oil,feed mills,grain storages is supported by skilled engineers they worked all over the world for important concerning food companies

COMPETENCE AND PROFESSIONALISM

We guarantee efficiency,competence and professionalism in the activities carried out,combined with a timely intervention and speed to our award winning assistance 24 hours a day,7 days a week .

TURNKEY PROJECT

The turnkey project is developed respecting precise executive steps :starting from the project based on the customer’s demands, the selection of machinery to assemble and related accessories. Subsequently ,it is fully installed,the consequend test,and after-sales service 24 hours a day, 7 days a week. We offer ability know-how and certificates according to the law

MANAGEMENT AND COORDINATION OF EXISTING FACILITIES

In addition to the turnkey design we offer installation services,dismantling,extension and transformation of mills,mill plants and extraction plants,silos,rice mills,oil mills,feed mills,grain storages,all done quickly and with the maximum efficiency, even in casa of displacements over long distances

Grinding and cambering rollers

doming on request

The aim of grinding is to obtain: a geometrically perfect roller, optimum axis alignment (that of the two end shafts in relation to the central body of the cylinder) and a surface that conforms to demand.

In the case of scratched rollers, this restoration operation can be partial or total;

depends on the state of wear of the scoring.

In the case of smooth rollers, the roller can also be curved on request.

The latter will allow the full length of the roller to be used due to the heating of the roller during grinding.

Rigging

The scoring operation is mainly carried out (for the first grinding passes such as B1/B2/B3 etc….)

The scoring capacity allows us to make between 125 and 1500 lines around the circumference of the roller and with line inclinations of up to 20%.

Sandblasting service

The sandblasting machine can accommodate rollers from 200 mm to 300 mm in diameter.

We are able to meet the needs of our customers from both the milling and oil industries to achieve an optimum level of extraction.

We offer the best sandblasting, doming and roughening service on the market.

Roughness on request.

Checking damaged end shafts

Because of the bearings that can damage the shaft seat, the end shafts must be in perfect condition before grinding or regrinding, otherwise they must be restored.

Packaging

Our rollers are packaged appropriately for transport with corrosion-proof film material and

VpCL-126 CORTEC anti condensation

Roller measurement and analysis

- Measurement of surface hardness

- Damage analysis

- Roller roughness measurement

- Qualitative roller analysis

- Scoring control

- Cylinder support

- 24h assistance

Heat treatment and reconditioning of rollers

- Roll mechanisation

- Roller cleaning

Replacing O’Rings and Sealing - Roller maintenance

Useful info

Call us

WRITE US

WHERE WE ARE

Via La Carrera, 140

Altamura (BA) – 70022